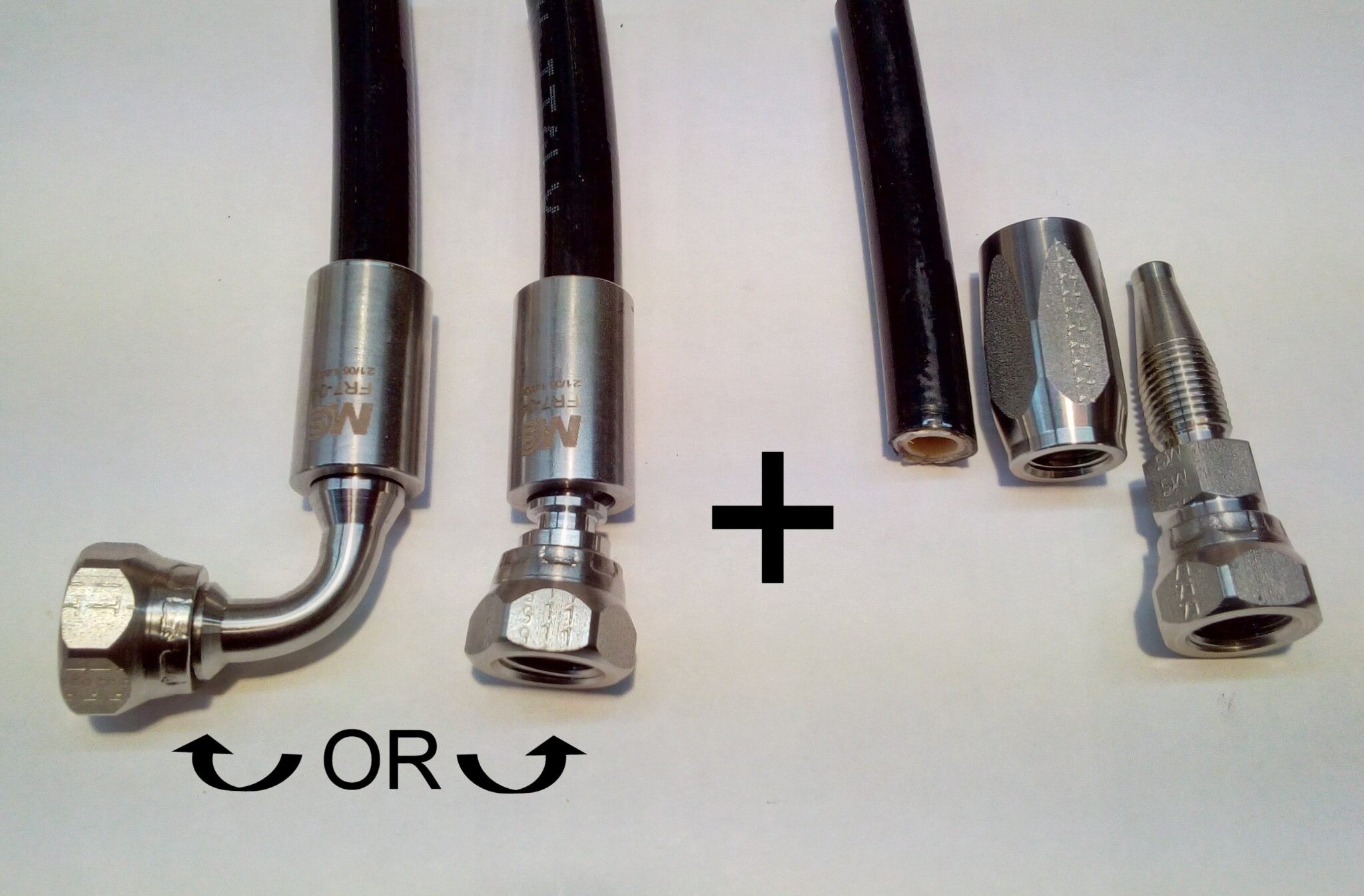

SAE 100 R7 1/4″ (200 bar) pressed tube with one 1/4″ Aisi 316L stainless steel fittings, 90° swivel female (or alternatively 180°) and one recoverable fitting by MCS Hydraulics. Length 4 meters. The high pressure 1/4 hose can be cut to the desired size before joining the recoverable fitting.

It is recommended not to use lengths longer than 5 meters to connect the last vessel to the pressure regulation valve. If a length of 5 meters or more is required, a 3/8″ hose with 1/4″ fittings must be used.

In case of longer hoses it is always good practice to use a larger diameter. Our office is available for consulting at the WhatsApp service number.

IN CASE OF DOUBT ALWAYS CALL OR WRITE. WE ARE HAPPY TO HELP!

|

|

TECHNICAL FEATURES OF THE HIGH PRESSURE 1 4 HOSE

Technical-constructive features:

Inner core in thermoplastic polyester, reinforcement in polyester textile and exterior covering in antiabrasion polyurethane stabilized against UV rays and resistant to hydrolysis and micro-organisms, suitable for outdoor applications in environments having high humidity and saline levels, pinpricked for conduction of air and compatible gases.

Applications:

Hoses of this series have been created for high pressure hydraulic applications in MARINE environments; this type of hose offers good flexibility at low temperatures and is particularly recommended for operating machines and lift trucks, which work at low temperatures.

Working temperature:

from -54°C to +100°C from -65°F to +212°F. Max. working temperature of air, water and water-based fluids is +70°C (158°F).

Use at low temperature only in static applications.

Working pressure:

Safety ratio 1:4

Vacuum rating:

0.93 bar; 700 mm Hg

High pressure 1/4 hose Specifications:

These hoses meet or exceed SAE J517 sec. 100R7, ISO 3949 and DNV-GL, MSHA Standards.

Lloyd’s Register TYPE APPROVAL Hoses.

HOSES INSTALLATION INSTRUCTION ACCORDING TO DIN 20066

To guarantee pressed hoses safety, life and feature, it is recommended:

– to respect the maximum temperature and working pressure

– to mount them correctly

– to chose the right fittings with relation to hoses length and installation conditions.It is strongly recommended to respect the following rules:

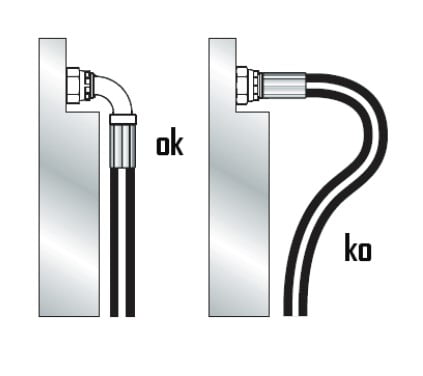

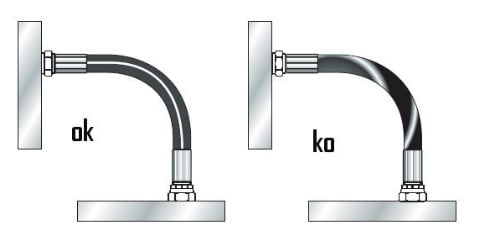

Torsion:

Do not apply any torsion.It may cause serious damage under pression.

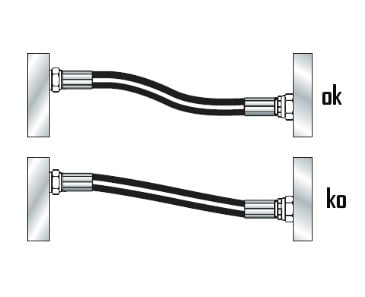

Length variation:

Another key factor is hose length, due to hose movements, a wrong length may cause surface wear and pressure drops. It is recommended to calculate a length greater than required; according to Sae and Din standards an hose under pressure can be extended (max +2%) or shortened (max -4%)

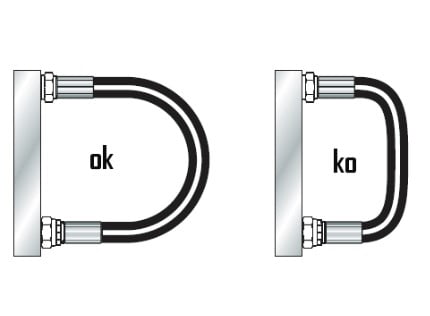

Bending Radius:

It is recommended to respect the minimumBending radius during assembly because bendsWith a lower radius would result in mechanicalStress and serious damages to metal threadsWhich would shorten working life, and reduceBurst pressure and resistance to max pressure. Excessive bending would neutralise the advantage of lower pressure drops in hose bends.

Choose the right fitting!!

Select the suitable fitting in order to avoid any stress to crimped hose.