INFORMATION ON THE TECHNICAL FEATURES

12 Volt Watermakers “ZERO” (55 l/h)

Input voltage: 12/24 V DC

Motors:

– M80.H70 12 Volt – 1250 rpm – 30 Ampere

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.35 Kg

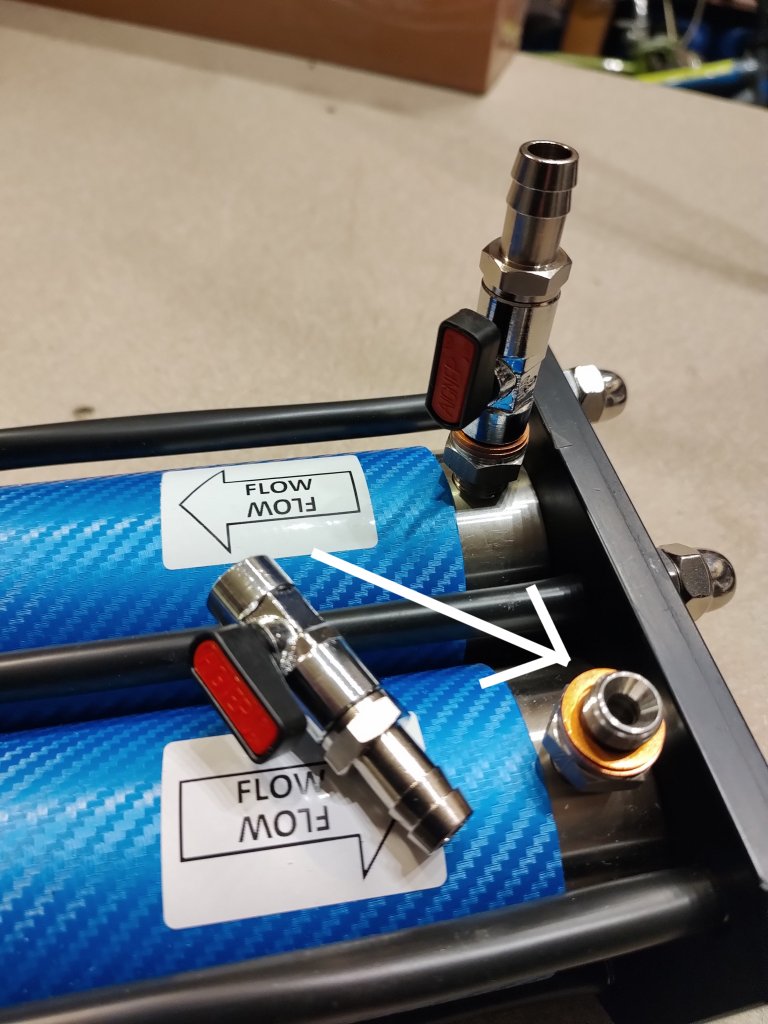

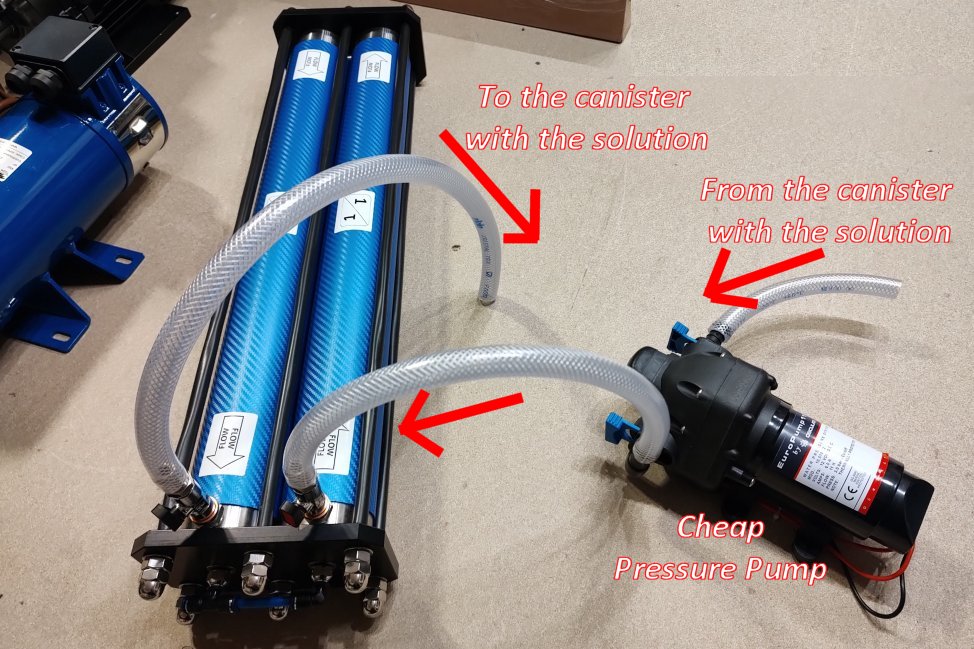

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

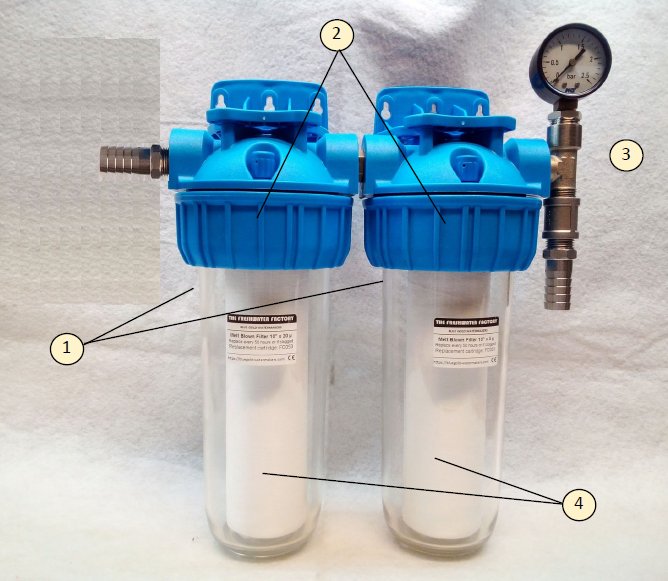

Standard pre-filtration: 10”DOE – 5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

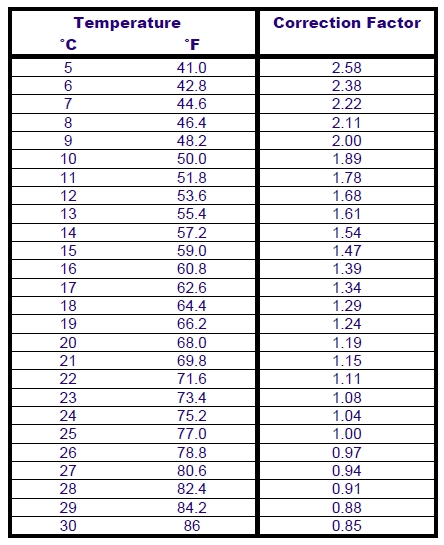

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-1 x Seawater Element (2,5” x 40”)

Water maker production amount*:

-55 Liters/Hour (1×2540 Membrane)

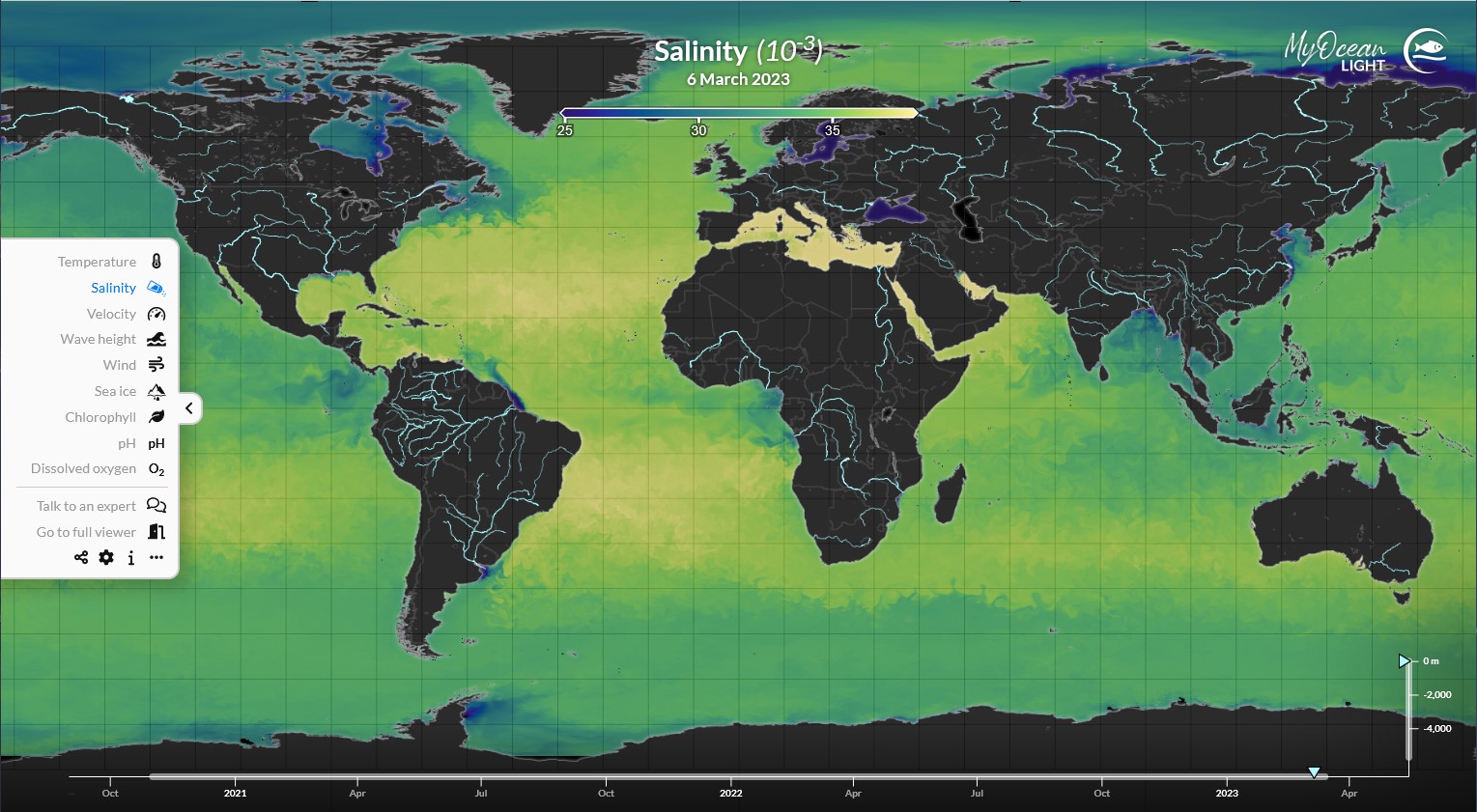

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure

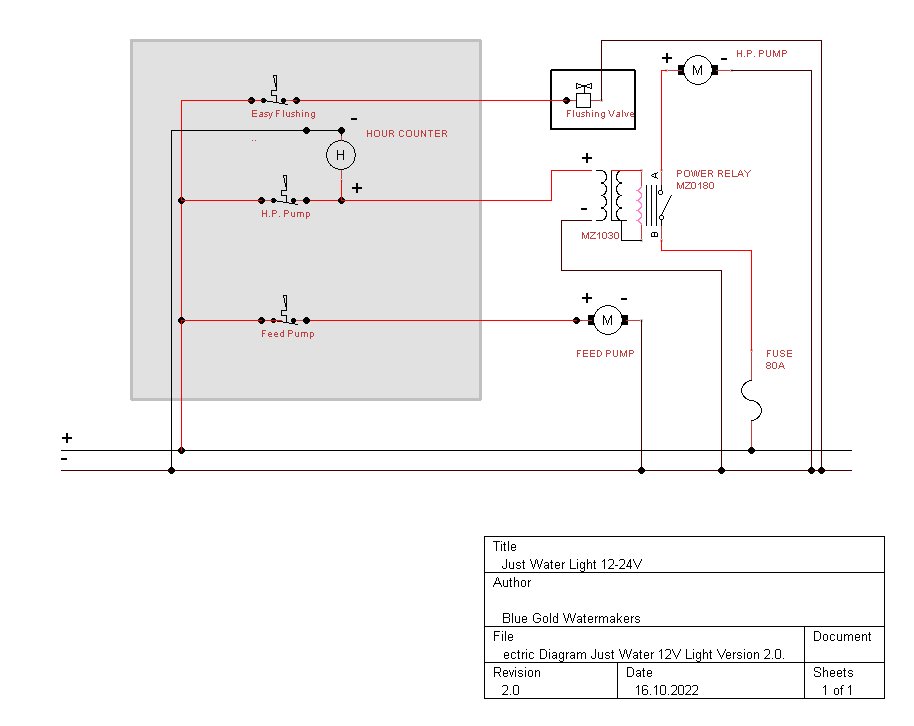

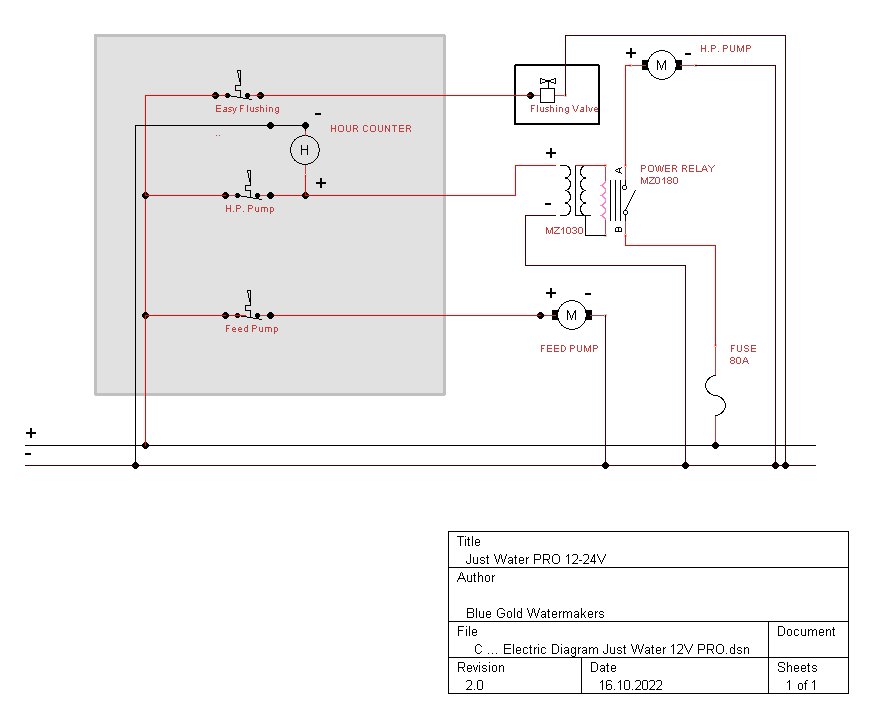

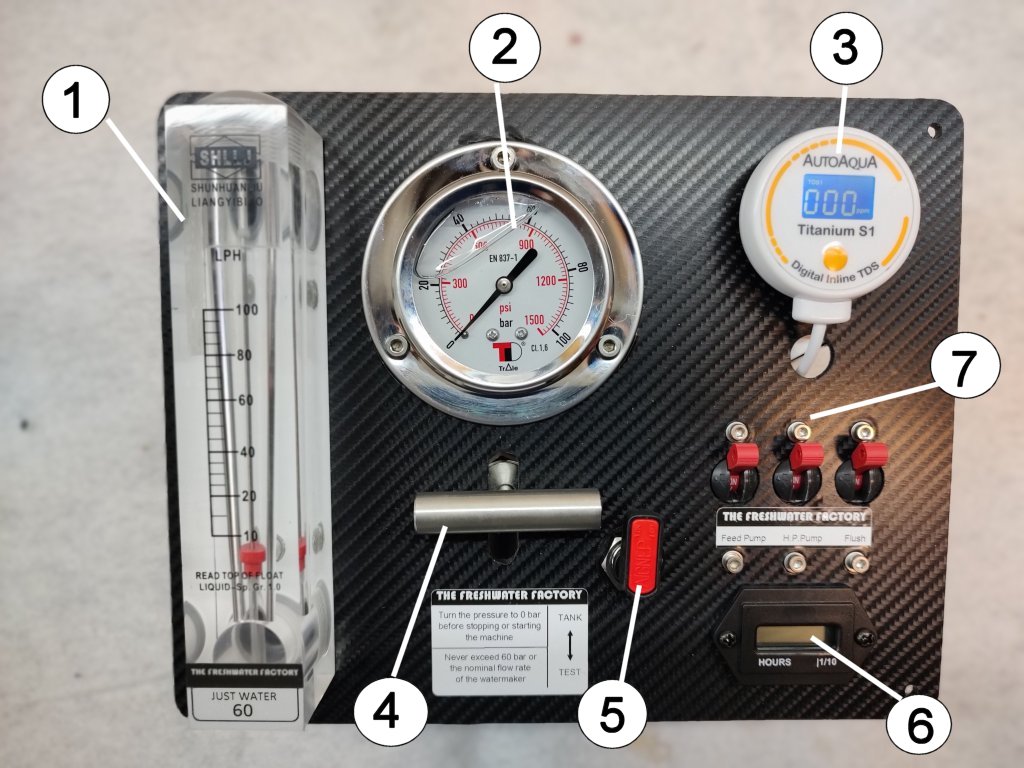

12/24 Volt Watermakers “JUST WATER” (60-80 l/h)

Input voltage: 12/24 V DC

Motors:

– M80.H140 12 Volt – 1700 rpm – 50 Ampere

– M80.H140 24 Volt – 1700 rpm – 34 Ampere

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.35 Kg

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

Standard pre-filtration: 10”DOE – 5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-1 x Seawater Element (2,5” x 40”)

-2 x Seawater Element (2,5” x 21”)

-3 x Seawater Element (2,5” x 21”)

Water maker production amount*:

-60 Liters/Hour (1×2540 Membrane)

-60 Liters/Hour (2×2521 Membranes)

-80 Liters/Hour (3×2521 Membranes)

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure

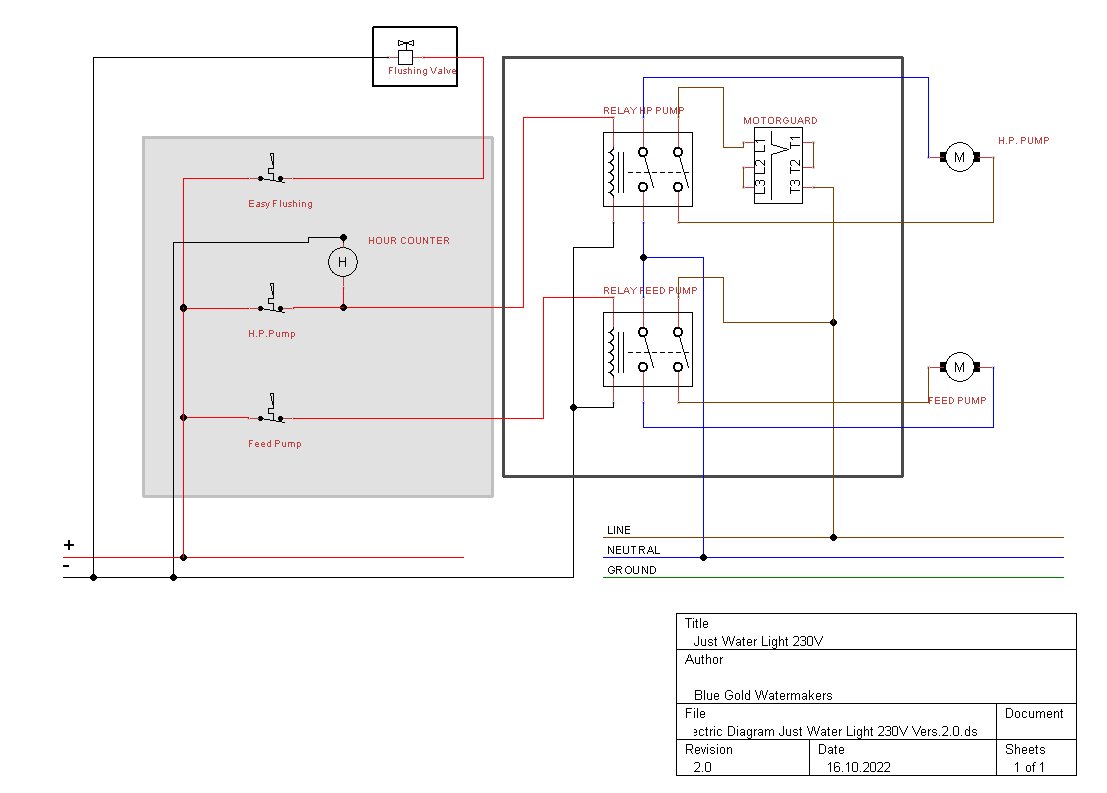

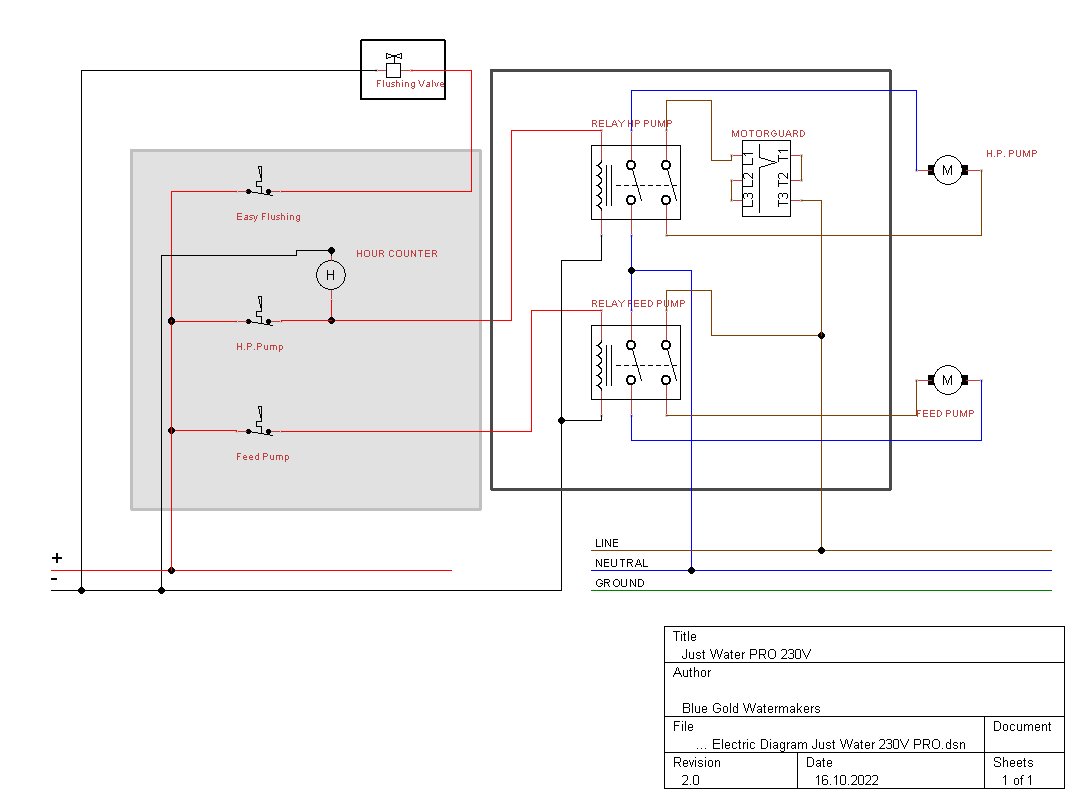

230 Volt (750 Watt) Watermakers “JUST WATER” (60-80 l/h)

Input voltage: Single phase 230 Volt AC (three phases 400 Volt on request)

Motor: MEC80 – 1450 rpm – 750 Watt (1 Hp)

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.35 Kg

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

Standard pre-filtration: 10”DOE – 5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-1 x Seawater Element (2,5” x 40”)

-2 x Seawater Element (2,5” x 21”)

-3 x Seawater Element (2,5” x 21”)

Water maker production amount*:

-60 Liters/Hour (1×2540 Membrane)

-60 Liters/Hour (2×2521 Membranes)

-80 Liters/Hour (3×2521 Membranes)

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure

230 Volt (1,1 kW) Watermakers “JUST WATER” (75-120 l/h)

Input voltage: Single phase 230 Volt AC (three phases 400 Volt on request)

Motor: MEC90 – 1450 rpm – 1100 Watt (1,5 Hp)

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.40 Kg

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

Standard pre-filtration: 10”DOE – 20+5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-1 x Seawater Element (2,5” x 40”)

-2 x Seawater Element (2,5” x 40”)

Water maker production amount*:

-75 Liters/Hour (1×2540 Membrane)

-120 Liters/Hour (2×2540 Membranes)

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure

230 Volt (1,5 kW) Watermakers “JUST WATER” (90-150 l/h)

Input voltage: Single phase 230 Volt AC (three phases 400 Volt on request)

Motor: MEC90 – 1450 rpm – 1500 Watt (2 Hp)

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.40 Kg

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

Standard pre-filtration: 10”DOE – 20+5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-1 x Seawater Element (2,5” x 40”)

-2 x Seawater Element (2,5” x 40”)

Water maker production amount*:

-90 Liters/Hour (1×2540 Membrane)

-150 Liters/Hour (2×2540 Membranes)

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure

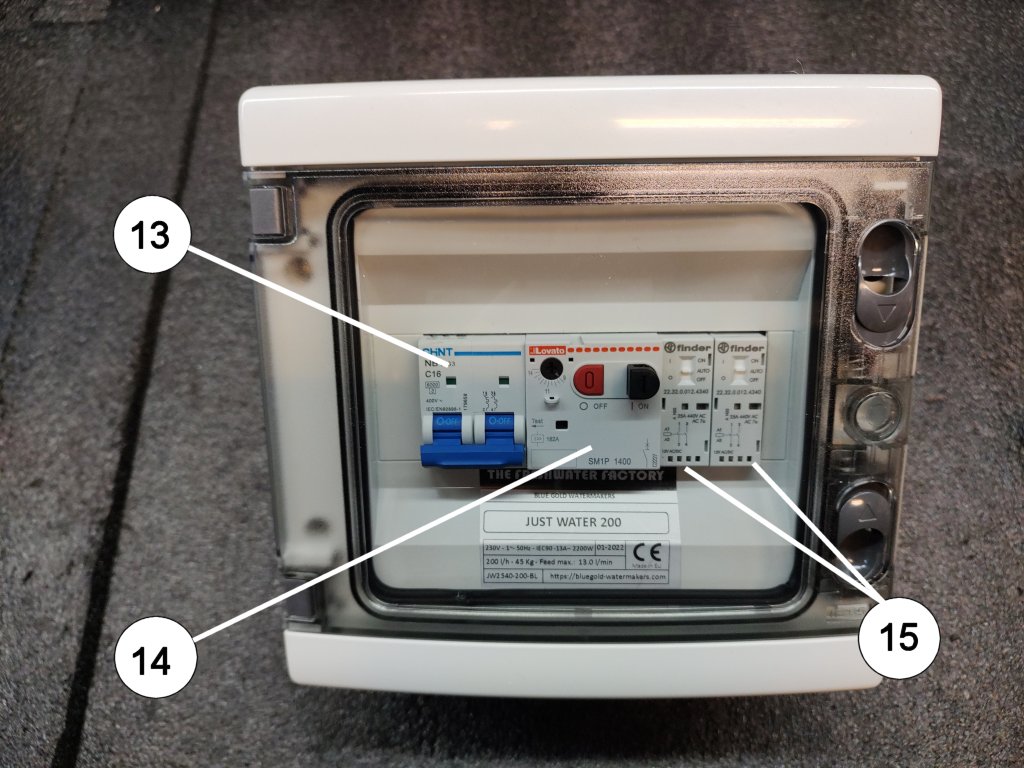

230 Volt (2,2 kW) Watermakers “JUST WATER” (200-250 l/h)

Input voltage: Single phase 230 Volt AC (three phases 400 Volt on request)

Motor: MEC90 – 1450 rpm – 2200 Watt (3 Hp)

Noise level: 68 db

Working pressure: Max. 60 Bar

Weight: ca.45 Kg

Seawater inlet pressure: 0,5 – 4,0 Bar

Flushing pressure: 1,0 – 4,0 Bar

Standard pre-filtration: 10”DOE – 20+5 Micron

Permeate TDS: < 500 ppm

Salt rejection: 99,4%

Seawater pH range :2 – 11

Seawater temperature range: +5 °C – +38 °C

Chlorine tolerance: < 0,1 ppm

Continuous operation: Max 40°C ambient temperature

RO Membranes:

-3 x Seawater Element (2,5” x 40”)

-4 x Seawater Element (2,5” x 40”)

Water maker production amount*:

-200 Liters/Hour (3×2540 Membrane)

-250 Liters/Hour (4×2540 Membranes)

*25°C water temperature, 32000 ppm salinity, 60 bar working pressure